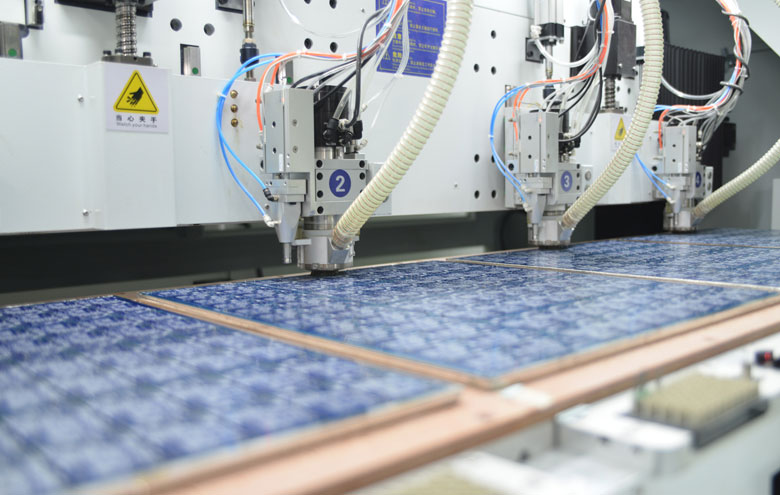

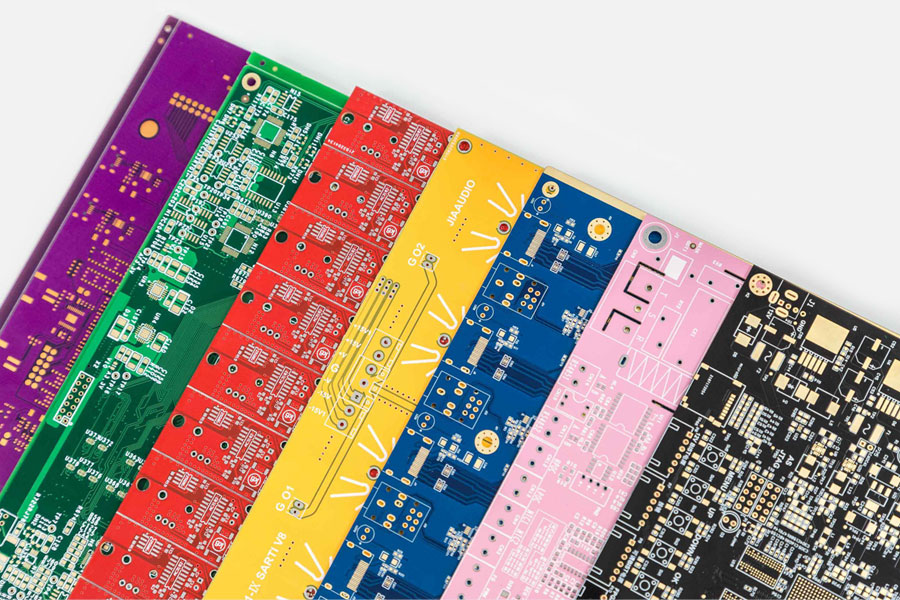

Customization Center

- circuit board

- Power circuit board

- Industrial control circuit board

- Security circuit board

- Medical circuit board

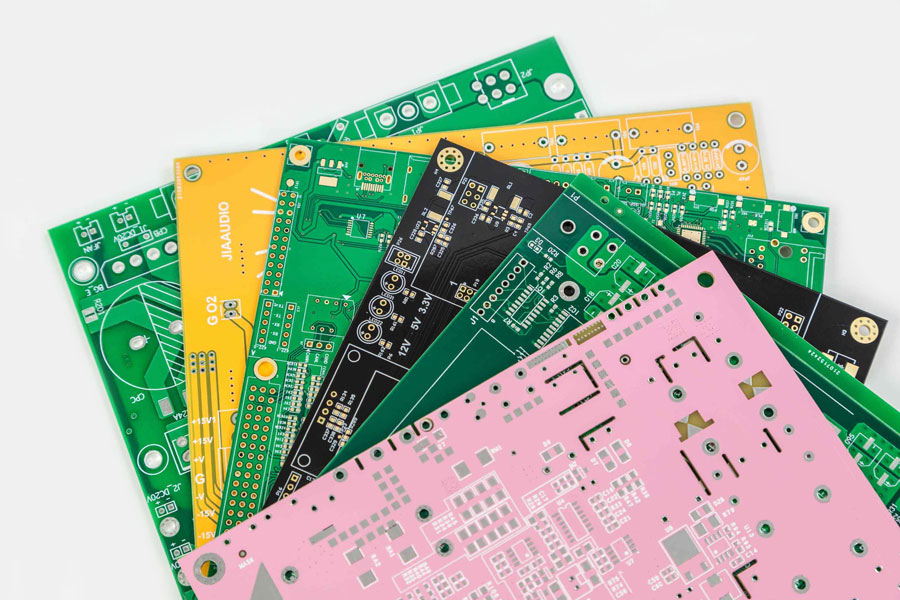

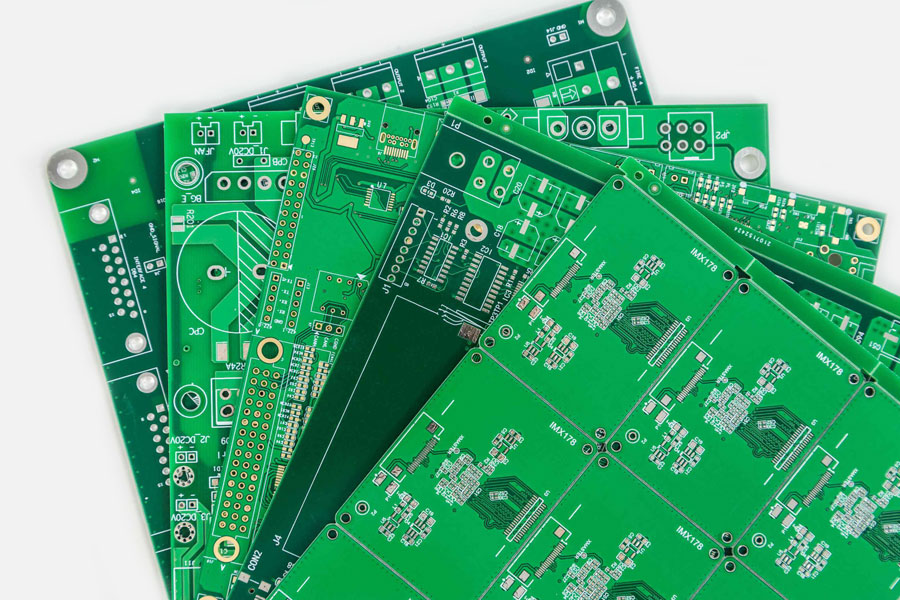

circuit board

Base material: FR4-S1000-2M

Plate thickness: 1.6mm

Number of layers: double-sided board

Process: lead-free tin spraying

Minimum drilling hole: 0.25mm

Minimum line width: 0.1mm

Minimum line spacing: 0.1mm

Features: Strict appearance requirements, line width and distance of 4mil

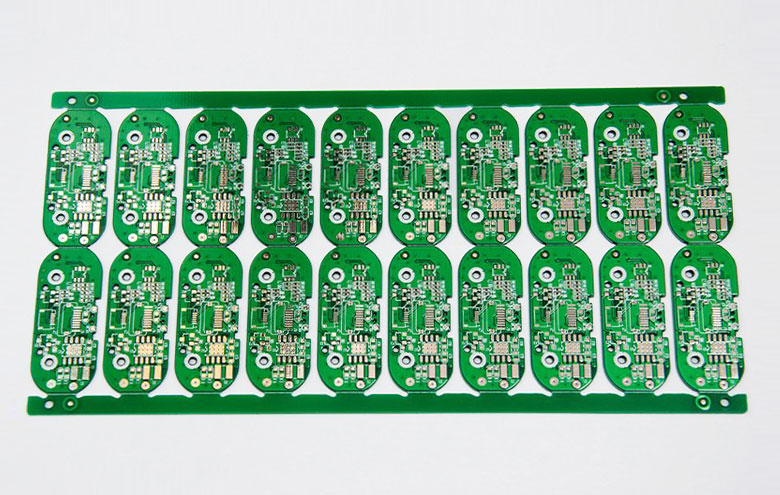

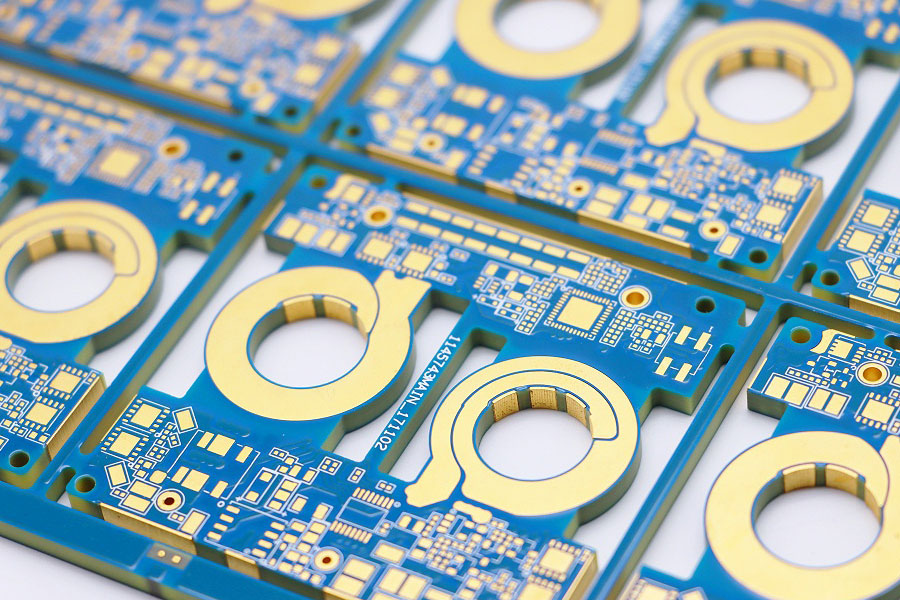

Power circuit board

Substrate: FR4

Plate thickness: 1.6mm

Number of layers: double-sided board

Process: lead-free tin spraying

Minimum drilling hole: 0.3mm

Minimum line width: 0.16mm

Minimum line spacing: 0.16mm

Features: High current, high reliability, thick copper plate

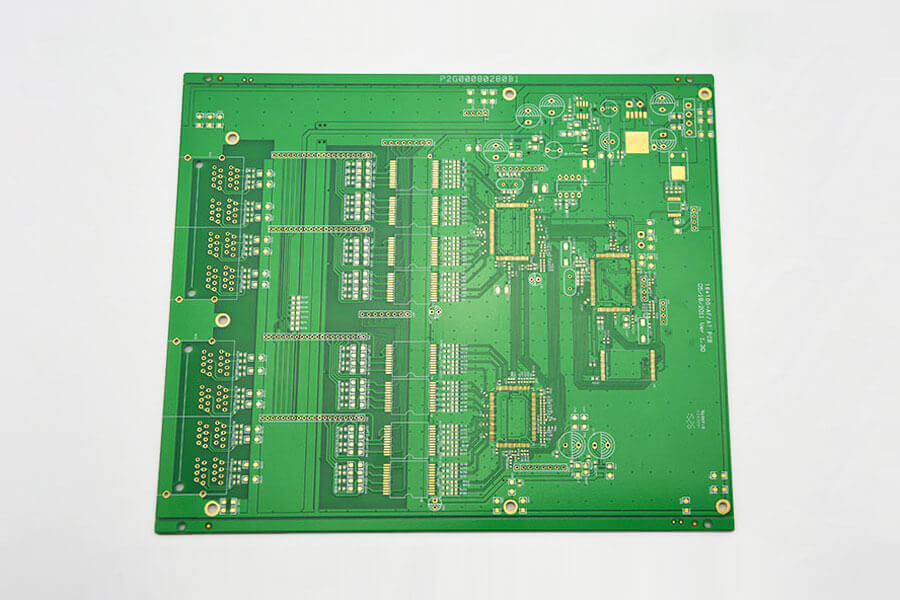

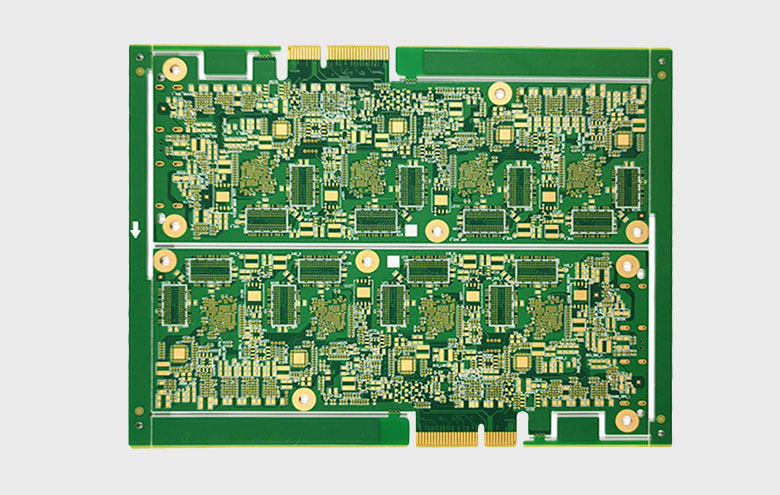

Industrial control circuit board

Base material: FR4-S1000-2M

Plate thickness: 1.6mm

Number of layers: four layer board

Process: Sinking Gold Plate

Minimum drilling hole: 0.25mm

Minimum line width: 0.16mm

Minimum line spacing: 0.16mm

Features: Gold finger, impedance board, gold finger requires beveled edges

Security circuit board

Base material: FR4-S1000-2M

Plate thickness: 1.6mm

Number of layers: Six layers of board

Craft: Sinking Gold+Gold Fingers

Minimum drilling hole: 0.25mm

Minimum line width: 0.1mm

Minimum line spacing: 0.1mm

Features: Hole copper 25um, thick copper plate, internal and external 4oz, blind buried hole plate